View More Products

Product Categories

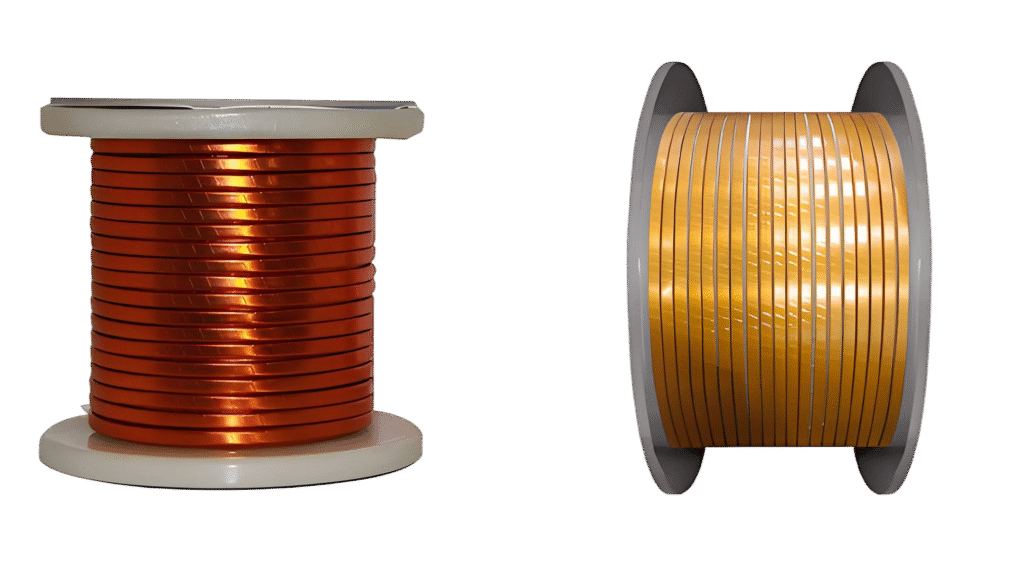

Kapton Wire

Kapton® (a polyimide film) wire represents the pinnacle of high-temperature and high-reliability magnet wire insulation. Its primary classification is based on the conductor material it sheathes—copper or aluminum—and the specific construction of its insulation system, which directly dictates its application domains.

1. Classification by Conductor and Structure:

The core distinction lies in the conductor: Kapton Copper Wire and Kapton Aluminum Wire. Copper is used where maximum conductivity, superior solderability, and mechanical strength are non-negotiable, despite higher weight and cost. Aluminum is chosen for extreme weight-sensitive or cost-driven applications where its lower conductivity is an acceptable trade-off. Beyond the conductor, the insulation is further classified by its construction type:

Single-Wrap Kapton: A single layer of polyimide tape, often with a thermal adhesive, providing excellent basic thermal protection.

Double-Wrap or Multi-Wrap Kapton: Multiple overlapping layers for enhanced dielectric strength, abrasion resistance, and reliability in high-voltage or harsh environments.

Composite Insulations: Kapton tape is frequently combined with other materials, most commonly a top coat of Teflon (FEP or PFA), to create a solderable, chemically inert, and extremely durable wire. This variant is often called “Kapton-Teflon” wire.

2. Primary Applications and Rationale:

The unique properties of Kapton—continuous operation up to 250°C, exceptional chemical resistance, high dielectric strength, and radiation resistance—make these wires indispensable in extreme environments.

Aerospace and Defense: Used in windings for actuators, flight control motors, and generators in aircraft and satellites, where weight (favoring Al) or performance (favoring Cu) dictates choice. They withstand wide temperature swings and outgas minimally in vacuums.

High-Temperature Industrial Motors: Essential for windings in furnace blowers, industrial dryer motors, and welding equipment where ambient temperatures would destroy standard enamel.

Downhole and Geothermal Equipment: The only choice for motors and sensors in oil/gas well logging tools, which face extreme heat, pressure, and corrosive fluids.

Critical Automotive: Used in high-stress under-hood applications, such as electric power steering motors or components near exhaust systems.

Medical and Scientific: Employed in the coils of miniature motors for surgical tools or within high-field MRI equipment, benefiting from the material’s reliability and purity.

Main Cooperative Partners

Product

Enameled wire

Litz Wire

Paper covered winding wire

Fiberglass covered bare winding wire

Fiberglass covered enameled wire

Submersible wire

Kapton wire

Accessories

About us

Company: Adora Magnetwire Industry Co.,Ltd.

Address: Guohuai Street,Gaoxin Zone,Zhengzhou,Henan,45000,China.

Email: info@adora-magnetwire.com

Whatsapp/Wechat: +86-17608429029

Official website: www.adora-magnetwire.com