View More Products

Product Categories

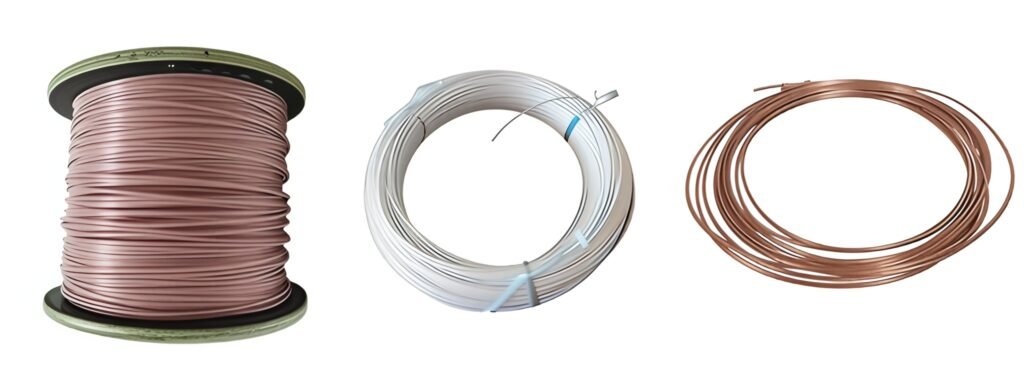

Submersible wire

The outer insulation layer of pump winding wires is a critical design element, engineered to provide robust physical and chemical protection beyond the base enamel. Common types include PP (Polypropylene), PE2+PA (Dual-layer Polyester-Amide), and XLPE+PA (Cross-linked Polyethylene with Polyamide), each serving distinct operational environments.

PP (Polypropylene) insulation offers excellent moisture resistance and good flexibility at a low cost. It is typically used for small to medium-sized submersible pumps handling clean water in residential and agricultural settings. Its primary role is to prevent water ingress and provide basic abrasion resistance during coil insertion into motor stators, ensuring reliability in damp conditions where chemical exposure is minimal.

PE2+PA (Dual-layer Polyester-Amide) represents a more advanced solution. The polyester (PE2) layer provides strong mechanical toughness and thermal stability, while the outer polyamide (PA) layer adds superb resistance to moisture, oils, and various chemicals. This makes it the ideal choice for circulating pumps in heating systems, industrial coolant pumps, and pumps handling mild chemical or oily fluids. The dual-layer construction ensures long-term integrity under continuous thermal cycling and exposure to aggressive media commonly found in industrial and automotive applications.

XLPE+PA (Cross-linked Polyethylene with Polyamide) is engineered for the most demanding environments. The cross-linked polyethylene (XLPE) core provides exceptional thermal endurance (often rated for 125°C or higher), excellent dielectric strength, and resistance to deformation under heat. Coupled with the outer PA layer’s chemical and abrasion resistance, this insulation is mandatory for heavy-duty submersible sewage pumps, chemical process pumps, and high-temperature hot water circulators. It withstands prolonged exposure to wastewater, harsh solvents, high temperatures, and mechanical stress, preventing insulation breakdown that could lead to motor failure.

In summary, the selection of outer insulation—PP for economical moisture protection, PE2+PA for balanced chemical-mechanical durability, and XLPE+PA for extreme thermal-chemical resilience—is a direct response to the specific fluid, temperature, and operational stresses a pump motor will face, ensuring optimized performance and longevity.

Main Cooperative Partners

Product

Enameled wire

Litz Wire

Paper covered winding wire

Fiberglass covered bare winding wire

Fiberglass covered enameled wire

Submersible wire

Kapton wire

Accessories

About us

Company: Adora Magnetwire Industry Co.,Ltd.

Address: Guohuai Street,Gaoxin Zone,Zhengzhou,Henan,45000,China.

Email: info@adora-magnetwire.com

Whatsapp/Wechat: +86-17608429029

Official website: www.adora-magnetwire.com